The Requirement

Simplifying Support for a Complex Machine

Operators and technicians working with the CAT 5500 often rely on physical manuals and verbal training, which can be inefficient, hard to access during maintenance, and prone to errors. The requirement was to create a user-friendly, on-device AR experience to offer instant access to critical operational guidance — from getting started to navigating key features and performing routine maintenance.

The Solution

An Augmented Reality Companion for CAT 5500

We designed a mobile AR app that allows users to place and interact with a virtual CAT 5500 machine. Through surface tracking, users access a quick start guide, feature highlights, and maintenance animations — all in real-time. The interface was optimized for industrial conditions, with simplified icons, glove-friendly design, and offline functionality.

Thought Process

Translating Complexity into Confidence

My focus was on usability and trust. How do we translate a machine manual into an interactive guide without overwhelming the user? I emphasized scenario-based AR design, ensuring each section of the app addressed a common pain point — like finding part locations, learning button functions, or performing time-sensitive repairs — with minimum friction and maximum clarity.

Research

Understanding Technician Pain Points and Equipment Complexity

I interviewed field engineers and support teams to identify real friction points. Key insights revealed the need for immediate, visual assistance and a faster understanding of system behavior without diving into dense manuals.

Opportunity

Reimagine Field Support Using AR Anchored to Real Equipment

We identified a gap between static documentation and real-time guidance. AR provided a way to bridge that — offering spatial context, animation-based walkthroughs, and layered interaction directly on or around the equipment, reducing dependency on external aids.

UX Strategy

Scannable. Simple. Scalable.

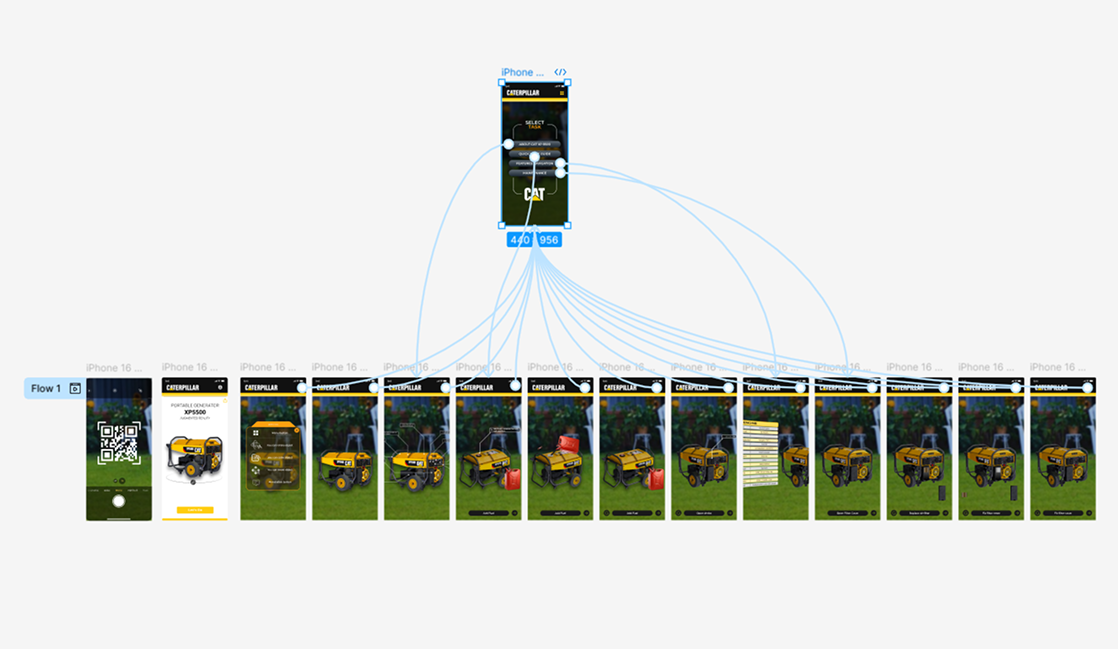

We defined a modular user flow:

- Scan the QR printed at machine

- Access the Quick Start Guide

- Tap to explore features (highlighted in 3D)

- View maintenance workflows via animated overlays

The UI used icons, color coding, and progressive disclosure to support minimal distraction in noisy, fast-paced environments.

Delivery

From Concept to Interface

After conceptual wireframes, I worked with designers to build the UI and asset structure, and with developers to implement it in Unity with SLAM-based tracking. The 3D model of CAT 5500 was optimized for performance across devices. We built, tested, and delivered an APK along with a usage guideline and scalability framework for future machine variants.

Feedback

Testing & Iteration Loop

Initial testers praised the tactile feel and logical flow. However, they found early popups text-heavy and interaction zones confusing in bright light. We iterated by simplifying callouts, using animation over description, and enhancing contrast and touch zones — making the experience more robust in real-world conditions.

Reflection

What I Learned as a Product Manager

This case taught me the power of designing for utility-first AR. I learned to prioritize what matters most in high-pressure field environments: speed, clarity, and confidence. It sharpened my skill to lead multidisciplinary teams where UX, tech, and real-world use collide. Ultimately, it reinforced that immersive tech shines when it solves—not just shows.